Recently, whether many friends have encountered the problem of abnormal vibration of the cone breaking machine. Whether it is a sand making machine or a cone breaking machine, there are quite a lot of comments in this regard. The reason for the abnormal vibration of the sand making machine has been introduced some time ago, this time we mainly analyze the common causes of the cone breaking vibration. The damage caused by abnormal vibration to the equipment is very large, the production capacity and efficiency will be greatly reduced, and the common reasons for the abnormal vibration of cone breaking are:

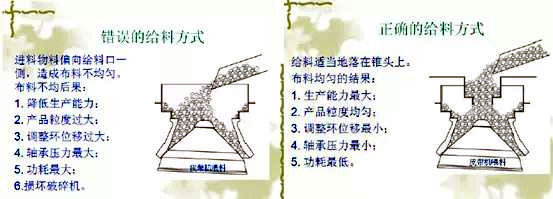

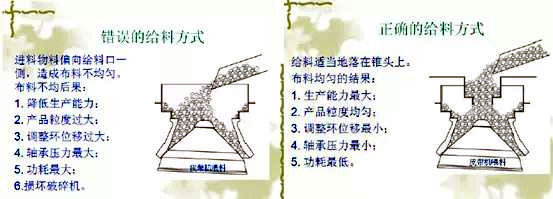

1. Too much or uneven feeding

When too much ore is fed and the load of cone breaking is exceeded, the equipment will not be able to crush the materials in the crushing cavity in time, resulting in accumulation of materials and abnormal vibration. (Multi-cylinder hydraulic cone breaking adjustment ring runout is the most obvious manifestation of overload)

When the feeding is uneven, such as concentrated feeding on one side (one-sided crushing), or large materials occupying one side and fine materials occupying one side, etc., it will cause vibration of the machine, and it will also cause the uneven force of the moving cone of the cone breakage, which will seriously affect the service life. .

2. Materials are blocked or enter unbreakable objects

When the content of ore powder in the crusher's ore is too much and wet, due to the small discharge opening of the crusher, the discharge opening often blocks the mine, resulting in frequent vibration of the crusher.

In addition, when non-crushed materials such as iron and steel and large pieces of ore enter the crushing chamber, the load of the crusher will increase sharply, causing vibration, and even shaft breakage and tooth punching. At this time, it is necessary to shut down and check in time to clean up hard debris.

3. Bearing temperature is too high

In the summer, the weather is hot and the temperature is gradually rising. Many equipment will have high temperature problems. The excessively high temperature of the broken cone bearing will also cause the equipment to vibrate. Therefore, you should always check whether the lubricating oil pipe is blocked and whether the selected grease is suitable. The lubricant is too dirty and needs to be replaced in time to prevent impurities from entering the bearing.

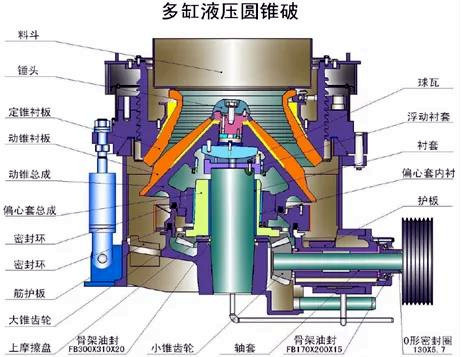

4. The tension of the spring is not enough

If you are using a spring cone break, pay attention to the tension of the spring. The spring installed around the frame is the safety device of the crusher. When the crusher enters the unbreakable object, the support ring and the adjustment ring supported on the spring strive to lift up and compress the spring, thereby increasing the ore discharge port, making the unusable The broken objects are discharged from the machine body to avoid the destruction of the machine parts. The tension of the spring has a great influence on the normal operation of the crusher.

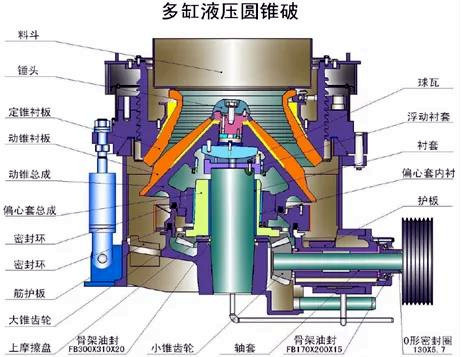

5. The equipment installation is unqualified or deviates from the original position

In terms of multi-cylinder hydraulic cone breaking, it requires horizontal vibration within +2mm and vertical vibration within +1mm. Failure to meet the installation surface will cause abnormal vibrations such as rack swing.

There are two installation surfaces, one is the basic installation surface, that is, the installation plane of the damping block; the other is the installation plane of the rack. The flatness of the two installation planes should be within 2mm, and the steel plate can be used to adjust the flatness.

In addition, after the cone is broken for a long time, the secondary concrete layer between the body and the foundation will become loose. The original installation leveling horn will move away from the original position with vibration, so that the body is in a level state, vibration Will intensify. Therefore, the basic level should be regularly calibrated according to the installation quality standards of the crusher body, so that the body is in a good operating state.

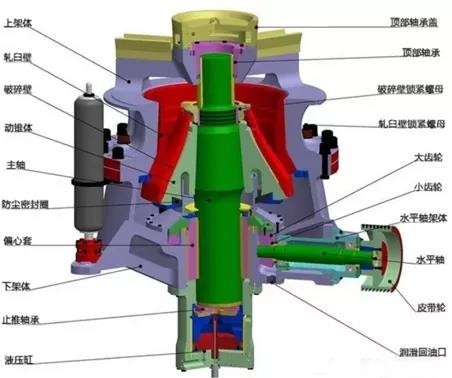

6. Improper installation of the coupling causes eccentricity

When assembling, the coupling between the broken horizontal drive shaft and the motor shaft should be aligned and installed according to the standard to avoid vibration caused by concentricity.

In addition, if the speed of the transmission shaft is too fast, it may cause vibration.

7. The gear mesh clearance is too large or too small

The rationality of the gear mesh clearance will also affect the vibration of the crusher. It should be assembled according to the standard top clearance and side clearance. It should not be too large or too small, otherwise it will cause the vibration of the crusher.

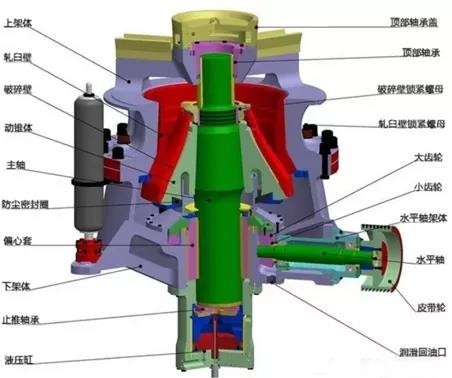

8. Wear of eccentric bushing

In the operation of cone breaking, the eccentric sleeve drives the main shaft or cone to provide the crushing force. The gap between the inner and outer surfaces of the eccentric shaft sleeve and the main shaft and the frame bushing ensures that the relative sliding surfaces of the eccentric shaft sleeve form Stable lubricating oil film to ensure normal operation, once the eccentric shaft and related parts wear, it may cause equipment vibration and affect work.

9. The clearance between the main shaft and the cone bushing is inappropriate

If the clearance between the main shaft of the cone crusher and the cone bushing is too large, the operation will be unstable, which will cause the machine body to vibrate and generate noise. If the clearance is too small, it will easily cause a shaft holding event.

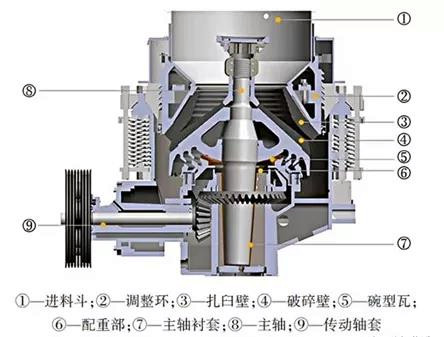

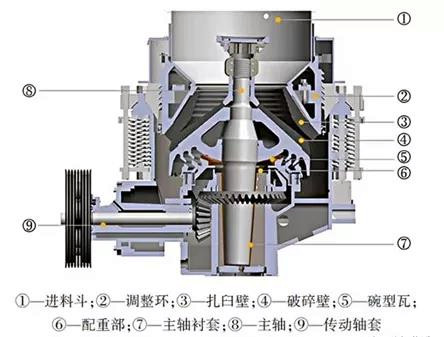

10. Loose matching surface between bowl-shaped support frame and rack

The bowl-shaped support frame is the support device of the crushing cone. The good technical condition of the matching surface of the bowl and the frame is of great significance to ensure the normal operation of the crusher. Due to the long-term operation of the cone break, the accuracy of this mating surface decreases, and the loosening of the mating surface causes vibration. In order to solve this problem, the matching surfaces of the bowl-shaped support frame and the rack need to be restored according to the original size standard.

Regarding other problems of cone crushing or other crushing sand making equipment, please call the service hotline or website message consultation!